1, high cost performance

The JM-ll series injection molding machine inherits the original design and high-quality manufacturing technology from Germany and Italy, and is assembled in China. It has a very high cost performance.

2. Personalization

According to the customer's choice and actual needs, the machine's mode-locking, injection, drive unit optimization combination, to meet all customer needs, and high efficiency.

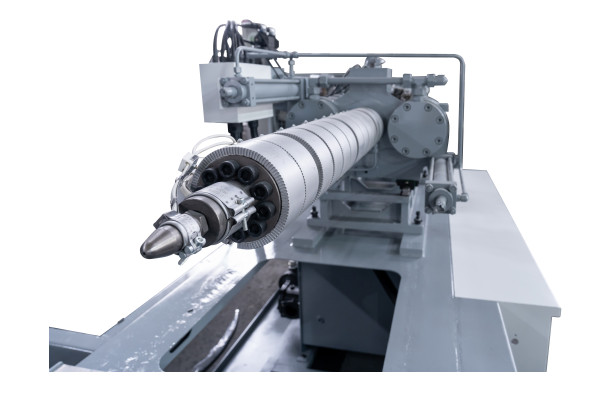

Injection Unit

* The injection mechanism adopts the modular design concept, and the same mold locking parts can be freely combined with injection parts of different sizes to meet the special needs of different customers for injection cells.

* The integrated platform support structure with precision bilinear guide rail ensures precise and fast start-up speed.

* Double beam transfer injection structure, further improve the injection accuracy.

* The steel pipe of the shooting table is connected with joints, and the weldless design makes maintenance and after-sales easier.

* Mobile nozzle shield, easier production and maintenance.

* The rubber head, rubber ring and rubber washer are made of high-quality imported materials SKD61; A complete range of screw design, can fully meet the raw materials and special processing requirements of injection molding.

* Double layer insulated cylinder protective cover, effective heat insulation, prevent burns, safer production process.

* Pre-molded motor adopts high torque and high speed hydraulic motor with high efficiency and high response.

* Roller slide structure is convenient for customers to change raw materials.

Hydraulic unit

* Standard precision energy-saving servo system, compared with the traditional injection molding machine energy saving effect of up to 20%-80%.

* Imported well-known brand hydraulic parts to ensure the reliability and rapid response of the machine.

* Visual, detachable fuel tank, oil line maintenance is more simple and convenient.

* The modular design of the transition valve block, oil circuit, function upgrade is easier, more convenient maintenance, effectively reduce pressure loss and improve response.

* Self-sealing magnetic oil filter, oil circuit maintenance is more convenient.

* Oil distribution science, easier maintenance.

DIN standard cone with sealing ring street, valve plate with G thread sealing plug, prevent oil pollution.

Electrical unit

ELECTRIC UNIT

* World famous electrical original, reliable quality.

* High quality color LCD controller, developed in cooperation with power system manufacturers, accurate control, faster response, powerful soft * standard three-color alarm light with buzzer, machine operation status at a glance.

* Can achieve modern networking management functions.

* Noise reduction and waterproof sponge strips are used in the electrical box and junction box to ensure the safety of the equipment.

* Machine procedures are designed according to European safety standards to protect the safety of operators.